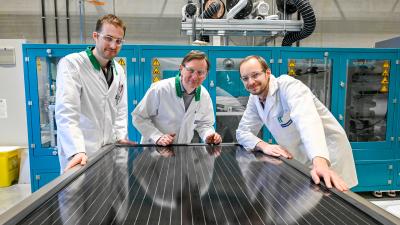

Jaan Leis, Mati Arulepp and Anti Perkson

Superior carbon-based materials for ultracapacitors

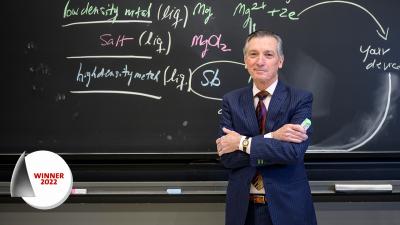

Winners of the European Inventor Award 2022

Ultracapacitors and batteries both supply electrical energy to machinery, but they deliver energy in different ways. Batteries offer a steady supply and are more suited to long, regular tasks. Conversely, ultracapacitors are best for short intense bursts of energy. Activated carbon is commonly used in ultracapacitor electrodes; however, it often contains contaminants. Pure graphene (a layer of carbon that is only one atom thin) is also a good conductor but does not provide a high level of energy density. After experimenting with different types of carbon-based materials, Leis, Arulepp and Perkson made a critical breakthrough: they optimised a material called curved graphene that boosts the power and longevity of ultracapacitors.

Curved graphene is an engineered form that "crumples" the graphene to increase its surface area on the electrode resulting in higher density to transmit power. It has a high chemical purity and is free of the toxic materials commonly found in other battery and capacitor technology, such as lithium or cobalt. According to the manufacturers Skeleton Technologies, their ultracapacitors can charge within 15 seconds, withstand over one million charge cycles and are up to 30% more efficient than regular batteries.

A breakthrough 20 years in the making

The Estonian inventors began researching new electrode technology in the early 2000s. Within a decade, they co-founded Skeleton Technologies to commercialise their research. Since then, the company has received over EUR 200 million in investments. It is now planning to scale up to the largest supercapacitor factory in the world, capable of producing 12 million units per year in a fully automated production line

Media gallery

Patent numbers:

Press materials

Contact

European Inventor Award and Young Inventors Prize queries:

european-inventor@epo.org Subscribe to the European Inventor Award newsletterMedia-related queries:

Contact our Press team#InventorAward #YoungInventors